Stocking Base Paper

Jumbo base paper rolls, later used to create toilet paper rolls, are brought in from the paper mill.

EN

KR모바일 메뉴보기

Mirae Well Life simply and sincerely, wishes everyone well.

Company

How our toilet paper rolls & kitchen paper towels are made

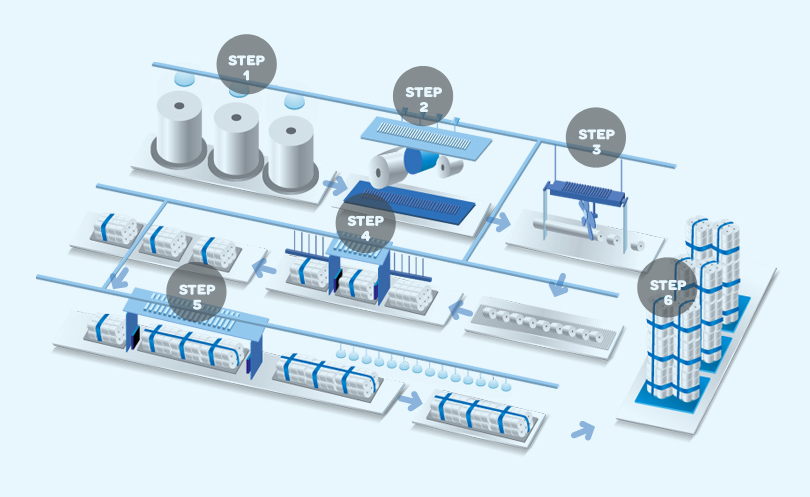

STEP1

Stocking Base Paper

Jumbo base paper rolls, later used to create toilet paper rolls, are brought in from the paper mill.

STEP2

Printing+Embossing/Rewinding

Base paper is rolled out, printed, embossed, and rewound around jumbo reels.

STEP3

Perforating

A rotating circular blade is used to cut the toilet paper to the correct height, which creates one standard-sized toilet paper roll.

STEP4

Wrapping

Each toilet paper roll is first wrapped separately. This creates the toilet paper roll you would normally see at supermarkets and shopping malls.

STEP5

Bundle Wrapping

Before being loaded onto pallets, multiple toilet paper rolls are wrapped in units to prevent product damage.

STEP6

Pallet Stacking and Storage

These units are then loaded onto pallets, wrapped, and moved to the warehouse.

How our facial tissues are made

STEP1

Stocking Base Paper

Jumbo base paper rolls, later used to create facial tissues, are brought in from the paper mill.

STEP2

Interfolding

Base paper is cut and interfolded so that a fresh tissue can pop out of the box as each tissue is removed. Separate tissues are counted into units, then moved to the paper cutting machine.

STEP3

Cutting

Each tissue is cut to the standard-sized facial tissue.

STEP4

Carton packaging

Now cut, the tissues are put into cartons. This allows the tissue to pop out of the box one by one.

STEP5

Wrapping

Tissue cartons are then wrapped in units. Imagine the carton-shaped facial tissues you would normally see at the drugstore!

STEP6

Box packaging

Before being loaded onto pallets, multiple facial tissue cartons are put into boxes to prevent product damage.

STEP7

Pallet Stacking and Storage

These units are then loaded onto pallets, wrapped, and moved to the warehouse.